Creating bends and curves in the tube while maintaining its structural integrity.

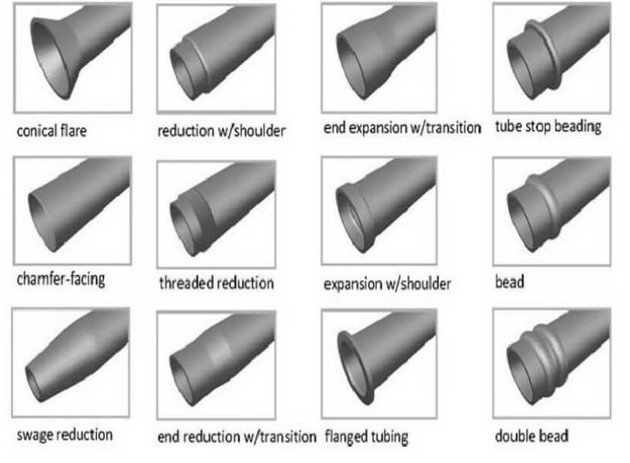

Increasing the diameter of a section of the tube, often for joining or fitting purposes.

Widening the end of the tube to create a flange for better connections.

Forming raised or recessed beads around the tube, often used to strengthen the tube or for fitting purposes.

Our forming processes utilize the latest technology and are executed by highly skilled professionals, ensuring that each tube meets exacting standards of quality and performance.

Perfect for creating high-performance exhaust systems, drive shafts, and other automotive components.

Essential for forming critical components that require exceptional precision and strength.

Ideal for producing precise and reliable tubing for various medical instruments and devices.

Enhance the performance and durability of tubes used in machinery, HVAC systems, and other industrial applications.

Perfect for creating aesthetically pleasing and functional components for appliances, furniture, and more.

We offer precise and customizable forming services to meet your unique specifications, ensuring a perfect fit for your application.

Our advanced techniques ensure a smooth and seamless finish, enhancing both the appearance and functionality of the tube.

Tube forming improve the structural integrity and strength of the tubes, making them more durable and reliable.

Suitable for a wide range of materials, including stainless steel, aluminum, copper, and various alloys.

Both processes allow for precise customization, making it possible to manufacture tubes that meet specific design criteria and functional requirements.

These methods can enhance the strength and durability of the tube, making it suitable for high-stress applications.

Achieves smooth and uniform finishes, which are often essential for aesthetic and functional purposes.

Applicable to a wide range of materials (stainless steel, aluminum, copper, etc.) and industries (automotive, aerospace, medical, industrial).

With years of experience and specialized knowledge, we deliver precision swaging and forming solutions that meet the highest industry standards.

Our advanced equipment ensures accuracy, consistency, and efficiency in every swaging and forming process.

We implement rigorous quality assurance protocols to ensure that each tube meets your exact specifications and performance standards.

We are committed to providing exceptional customer service, from initial consultation and design to final production and delivery, ensuring your complete satisfaction.